Decoding the Enigma of No Pressure Switch Symbols

Imagine a system where safety relies on the absence of pressure. This is where the often-overlooked no pressure switch steps in, a critical component in various industrial and domestic applications. But what about the markings that define its function? Understanding the no pressure switch symbol is crucial for effective system operation and maintenance. This article delves into the intricacies of these symbols, exploring their meaning, variations, and importance.

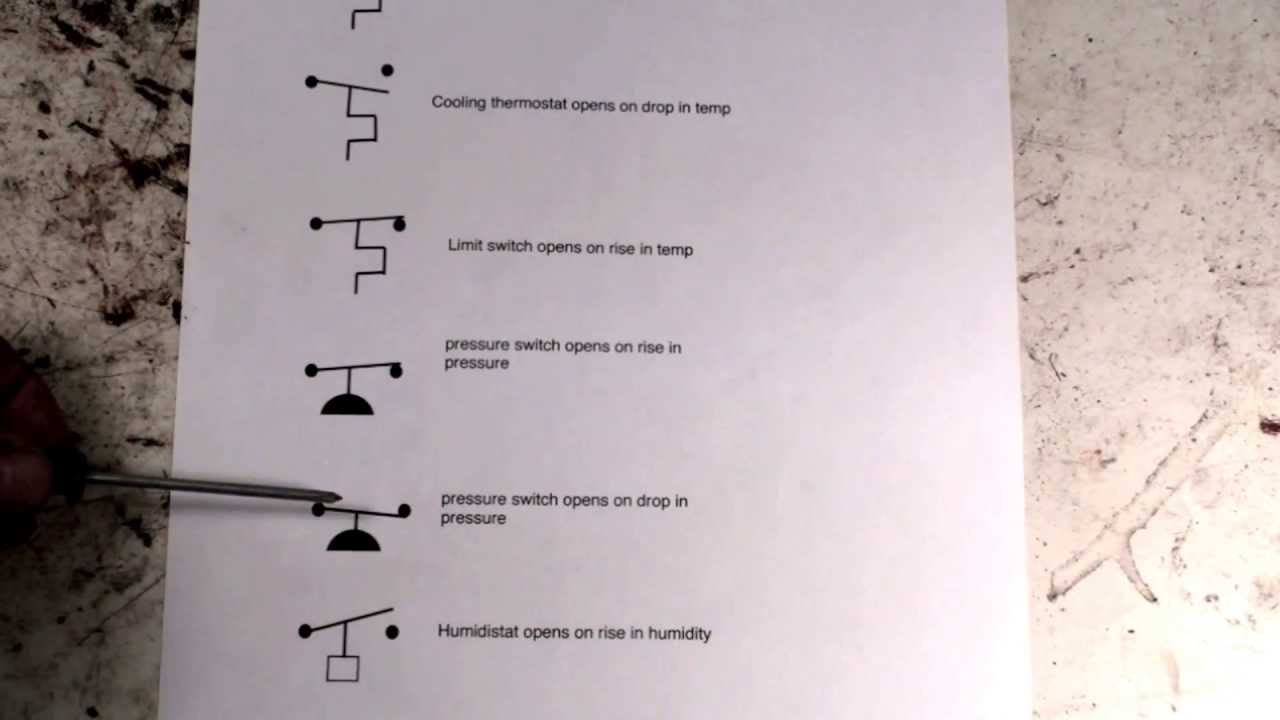

Pressure switches are ubiquitous, found in everything from HVAC systems to industrial pumps. They act as sentinels, monitoring pressure levels and triggering actions when predetermined thresholds are met. The no pressure switch, a specific type of pressure switch, activates when pressure falls below a set point. This unique characteristic necessitates distinct symbolic representation to differentiate it from other pressure-sensing devices. Recognizing the no pressure switch indicator is paramount for technicians, engineers, and anyone interacting with these systems.

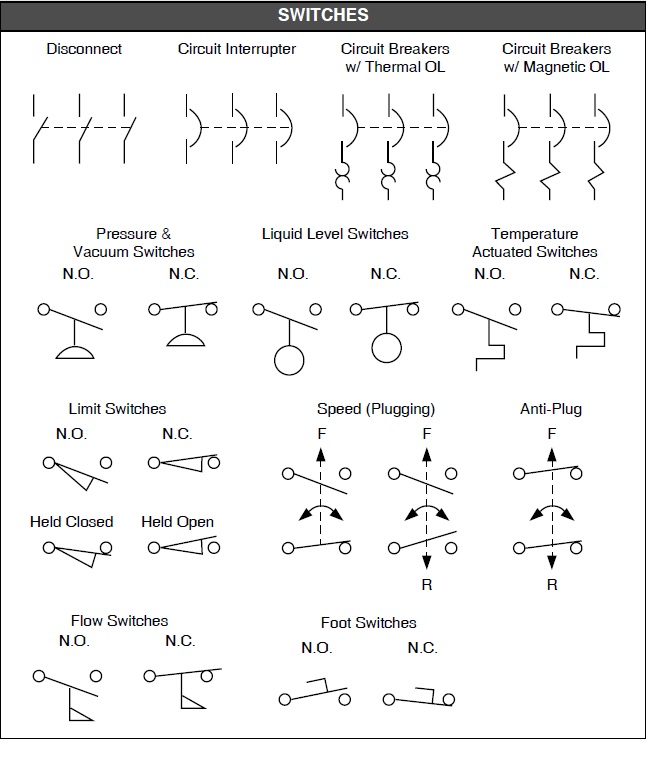

While a universally standardized "no pressure switch symbol" doesn't exist in the same way that some electrical symbols do, common representations often involve a depiction of a switch contact opening as pressure decreases, sometimes accompanied by an arrow indicating the direction of pressure change or a stylized depiction of a diaphragm or bellows. Understanding these variations and the underlying principles they represent is essential for accurately interpreting system diagrams and schematics.

Historically, pressure switch indicators evolved alongside the development of pressure control technology. Early representations were often simplistic, evolving into more nuanced symbols reflecting the increasing complexity of these devices. The development of international standards and industry best practices has led to a greater degree of consistency, though variations still exist. Tracing this evolution provides context for the symbols we see today and highlights the importance of referencing specific manufacturer documentation.

The significance of accurate no pressure switch representation cannot be overstated. Misinterpreting a symbol can lead to improper installation, faulty operation, and potentially hazardous situations. Imagine a scenario where a normally closed pressure switch symbol is mistaken for a no pressure switch symbol. The system might operate under undesired conditions, compromising safety and efficiency. Therefore, accurate and unambiguous symbolic language is vital for clear communication and proper system function.

Interpreting a diagram featuring a no pressure switch requires understanding the context of the system. Manufacturers often provide detailed documentation outlining the specific symbols used. Pay attention to accompanying labels, notes, and the overall system schematic to get a complete picture of the switch’s function.

Benefits of understanding these symbols include improved troubleshooting, easier system maintenance, and enhanced safety. Accurate interpretation allows technicians to quickly identify and rectify issues, minimizing downtime and preventing potential hazards. For example, recognizing a malfunctioning no pressure switch in a ventilation system can prevent dangerous build-up of fumes.

While a comprehensive step-by-step guide for interpreting every possible symbol variation is beyond the scope of this article, a key recommendation is to always consult the manufacturer’s documentation. This will provide the most accurate and relevant information for the specific switch in question. Websites specializing in industrial automation and control systems can also be valuable resources.

Advantages and Disadvantages of Standardized No Pressure Switch Symbols

| Advantages | Disadvantages |

|---|---|

| Improved communication and understanding among technicians. | Potential for confusion if standards are not widely adopted or followed. |

| Simplified troubleshooting and maintenance. | Difficulty in representing the nuances of specific switch functions within a standardized symbol. |

A best practice when dealing with pressure systems is to verify the function of the no pressure switch through physical inspection and testing. This ensures that the symbol accurately reflects the device’s behavior and that the switch is functioning as intended.

One real-world example of a no pressure switch application is in a vacuum system. The switch ensures the vacuum pump doesn't operate if the pressure is too low, preventing damage to the pump. Another example is in air compressors, where a no pressure switch prevents the compressor from starting if there isn't sufficient air pressure in the tank.

A common challenge is the lack of standardization across different manufacturers. Consulting datasheets and manuals is crucial to overcome this.

Frequently Asked Questions

Q: What does a no pressure switch do? A: It activates a circuit when pressure drops below a set point.

Q: How are no pressure switches used in HVAC systems? A: They can prevent operation if duct pressure is insufficient.

Q: Are there different types of no pressure switch symbols? A: Variations exist; consult manufacturer documentation.

A helpful tip is to familiarize yourself with the symbols used in your specific industry or application. This will improve your ability to interpret diagrams and troubleshoot systems effectively.

In conclusion, understanding no pressure switch symbols is vital for the safe and efficient operation of various systems. While standardized symbols are beneficial, variations exist, and consulting manufacturer documentation is crucial. By appreciating the historical context, recognizing the importance of accurate interpretation, and implementing best practices, technicians and engineers can ensure the proper functioning of these critical components, preventing potential hazards and optimizing system performance. Further research into pressure control systems and their associated symbols is highly encouraged for anyone working with these technologies. Understanding these seemingly small details can make a big difference in safety and efficiency. Taking the time to learn the intricacies of no pressure switch indicators empowers you to confidently navigate system diagrams, troubleshoot effectively, and contribute to a safer operational environment.

no pressure switch symbol | Kennecott Land

Pressure Switch Schematic Symbol | Kennecott Land

Symbol For Switch In Circuit | Kennecott Land

Disgusto Rebelión Torpe pressure sensor symbol fama Amarillento No de moda | Kennecott Land

Disgusto Rebelión Torpe pressure sensor symbol fama Amarillento No de moda | Kennecott Land

Do Not Switch on Symbol Sign Vector Illustration Isolate on White | Kennecott Land

Motor Control Circuits Electrical Machines | Kennecott Land

Disgusto Rebelión Torpe pressure sensor symbol fama Amarillento No de moda | Kennecott Land

Limit Switch Schematic Symbol | Kennecott Land

Pressure Switch Schematic Symbol | Kennecott Land

no pressure switch symbol | Kennecott Land

Electrical Schematic Symbols Pressure Switch | Kennecott Land

Pressure Switch Pid Symbol | Kennecott Land

Pressure Switch Schematic Symbol | Kennecott Land

Draw the appropriate Pressure Switch Symbol | Kennecott Land