Ford 6.7 Powerstroke Fuel Injector Replacement Guide

Facing rough idling or decreased fuel efficiency in your Ford 6.7 Powerstroke? These symptoms could point to faulty fuel injectors. Replacing these components can be a significant undertaking, but understanding the process can make it less daunting. This guide aims to simplify the complexities of extracting and replacing fuel injectors in the 6.7 Powerstroke diesel engine.

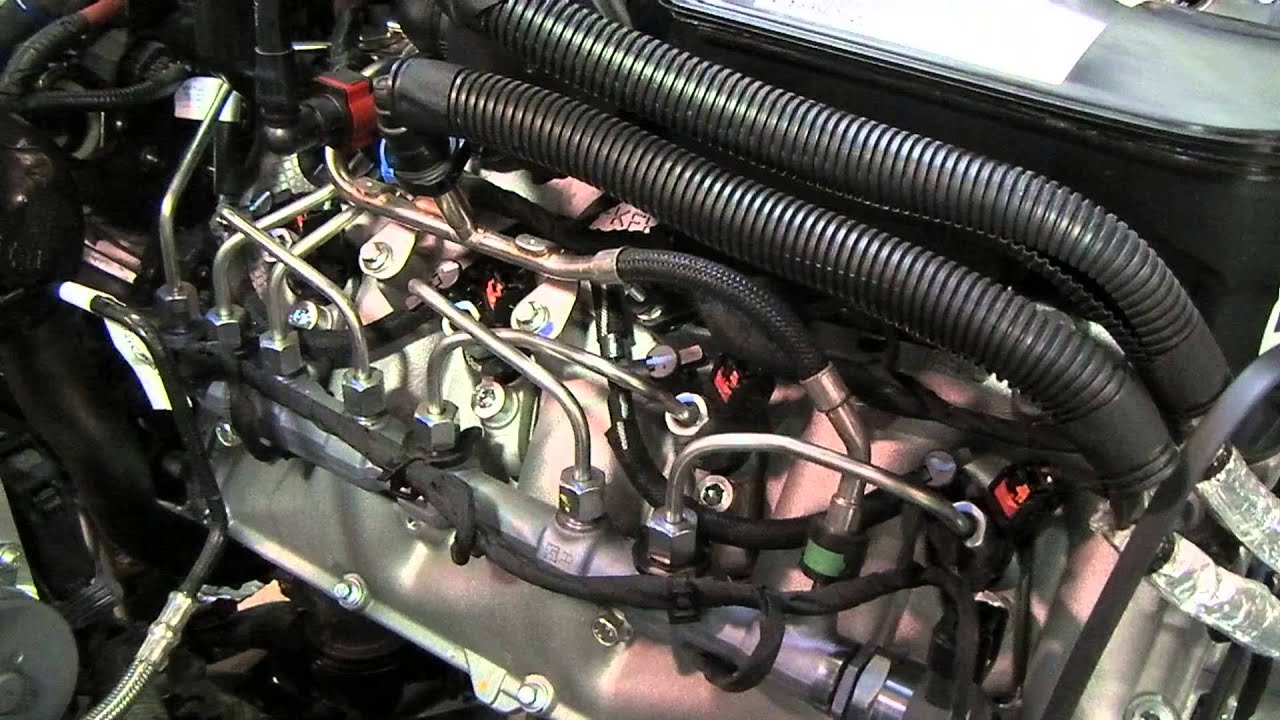

The 6.7L Powerstroke diesel engine, a staple in Ford's Super Duty lineup since 2011, represents a significant leap in diesel technology. Its fuel injection system plays a vital role in delivering power and efficiency. However, like any complex mechanism, these injectors can eventually wear out or malfunction. Knowing when and how to address these issues is crucial for maintaining optimal engine performance and longevity.

Replacing the fuel injectors on a 6.7 Powerstroke is not a simple oil change; it's a more involved procedure requiring some mechanical aptitude and specialized tools. The process involves accessing the injectors, carefully removing the old units, and installing new ones with the correct torque specifications. Overlooking any step can lead to further complications, highlighting the importance of understanding each phase of the task.

Historically, diesel fuel injector technology has evolved from simpler mechanical systems to the sophisticated electronically controlled injectors found in the 6.7 Powerstroke. These modern injectors precisely control fuel delivery for optimal combustion, contributing to the engine's power and efficiency. This precision, however, also means these components are more sensitive and require specific procedures for removal and replacement.

Proper function of the fuel injectors is paramount for several reasons. They directly impact engine performance, fuel economy, and emissions. Faulty injectors can lead to reduced power output, increased fuel consumption, rough idling, and excessive smoke. Addressing these issues through injector replacement is essential for restoring the engine to its intended performance and ensuring efficient operation.

One benefit of replacing worn injectors is improved fuel economy. When injectors malfunction, they can deliver an incorrect amount of fuel, leading to wasted fuel and reduced mileage. New injectors ensure precise fuel delivery, optimizing combustion and improving fuel efficiency.

Another advantage is restored engine performance. Worn injectors can hinder power output and cause rough idling. New injectors restore smooth operation and revitalize engine performance, ensuring the truck runs as designed.

Reduced emissions are a third benefit. Faulty injectors can contribute to increased emissions. Replacing them helps bring the engine back within acceptable emissions standards and promotes cleaner operation.

Preparation is key. Gather necessary tools like a torque wrench, socket set, and fuel line disconnect tools. Disconnect the batteries and relieve fuel system pressure before starting any work.

Gain access to the injectors by removing any necessary components like the valve covers and fuel rails.

Carefully disconnect electrical connectors and fuel lines from each injector before removing them.

Install the new injectors, ensuring they are properly seated and torqued to the manufacturer's specifications.

Reconnect all electrical connectors, fuel lines, and other removed components. Prime the fuel system and check for leaks before starting the engine.

Advantages and Disadvantages of DIY Injector Replacement

| Advantages | Disadvantages |

|---|---|

| Cost savings compared to professional service | Potential for damage if not done correctly |

| Sense of accomplishment | Time-consuming process |

| Learning experience | Requires specialized tools |

Best Practices:

1. Use the correct torque specifications: Over-tightening or under-tightening can damage the injectors or cause leaks.

2. Keep the work area clean: Contamination can cause injector failure.

3. Use quality replacement parts: Aftermarket injectors might not meet the same standards as OEM parts.

4. Consult a service manual: Follow the manufacturer's specific instructions for your engine model.

5. Consider professional help: If unsure about any step, seek professional assistance to avoid potential issues.

FAQs:

1. How often should I replace my injectors? Typically, injectors can last 100,000 miles or more, but it depends on usage and maintenance.

2. What are the signs of bad injectors? Common signs include rough idling, reduced fuel economy, and excessive smoke.

3. Can I replace just one injector? While possible, it's generally recommended to replace all injectors simultaneously.

4. What tools do I need? You'll need a torque wrench, socket set, fuel line disconnect tools, and potentially other specialized tools.

5. How long does the process take? It can take several hours, depending on your experience and the specific vehicle.

6. Can I drive with bad injectors? It's not recommended, as it can lead to further engine damage and reduced performance.

7. How much does professional replacement cost? Costs vary depending on location and labor rates.

8. What are the best brands of replacement injectors? OEM injectors are generally recommended, but reputable aftermarket brands also exist.

Tips and Tricks:

Label all connectors and lines to ensure correct reassembly. Use a thread sealant on injector hold-down bolts to prevent leaks. Prime the fuel system thoroughly after installation.

Replacing fuel injectors on a 6.7 Powerstroke diesel engine is a detailed process that requires attention and care. By understanding the steps involved, taking precautions, and following best practices, you can successfully complete this task and restore your truck's performance. While a challenging project, the benefits of improved fuel economy, restored engine power, and reduced emissions make the effort worthwhile. Remember to consult a service manual specific to your vehicle model year and seek professional assistance if needed. This guide is a starting point, and due to the complexity of this system, always prioritize safety and accuracy throughout the process. This meticulous approach will contribute to the overall health and longevity of your 6.7 Powerstroke engine.

64 Powerstroke Fuel System Diagram | Kennecott Land

67 Powerstroke Fuel System Diagram | Kennecott Land

Car Truck Fuel Pumps Motorcraft Engine Oil Pressure Sensor67L Ford | Kennecott Land

Ford 64 Twin Turbo Diesel Problems | Kennecott Land

Ford 60 Diesel Engine Turbo Hoses Diagram | Kennecott Land

Replacing Injectors On 67 Powerstroke | Kennecott Land

67 Powerstroke Fuel Injector Return Line | Kennecott Land

ford 6.7 powerstroke fuel injector removal | Kennecott Land

Fuel Filters For 2015 67 Powerstroke at Anita Klein blog | Kennecott Land

Ford 67 Powerstroke Cooling System | Kennecott Land

Replacing Injectors On 67 Powerstroke | Kennecott Land

2003 Ford 60 Powerstroke Fuel System Diagram | Kennecott Land

Best Year For 73 Powerstroke Engine | Kennecott Land

2020 Ford Powerstroke Fuel Filter | Kennecott Land

1995 73 Powerstroke Fuel Line Diagram | Kennecott Land