Honda Element Axle Nut Torque: Essential Guide for DIY Maintenance

Ensuring the safety and longevity of your Honda Element involves understanding various aspects of its maintenance, including the crucial role of proper axle nut torque. Overlooking this seemingly small detail can lead to significant problems down the road, from annoying vibrations to potentially dangerous wheel detachment. This comprehensive guide will delve into the world of Honda Element axle nut torque, equipping you with the knowledge to confidently tackle this essential maintenance task.

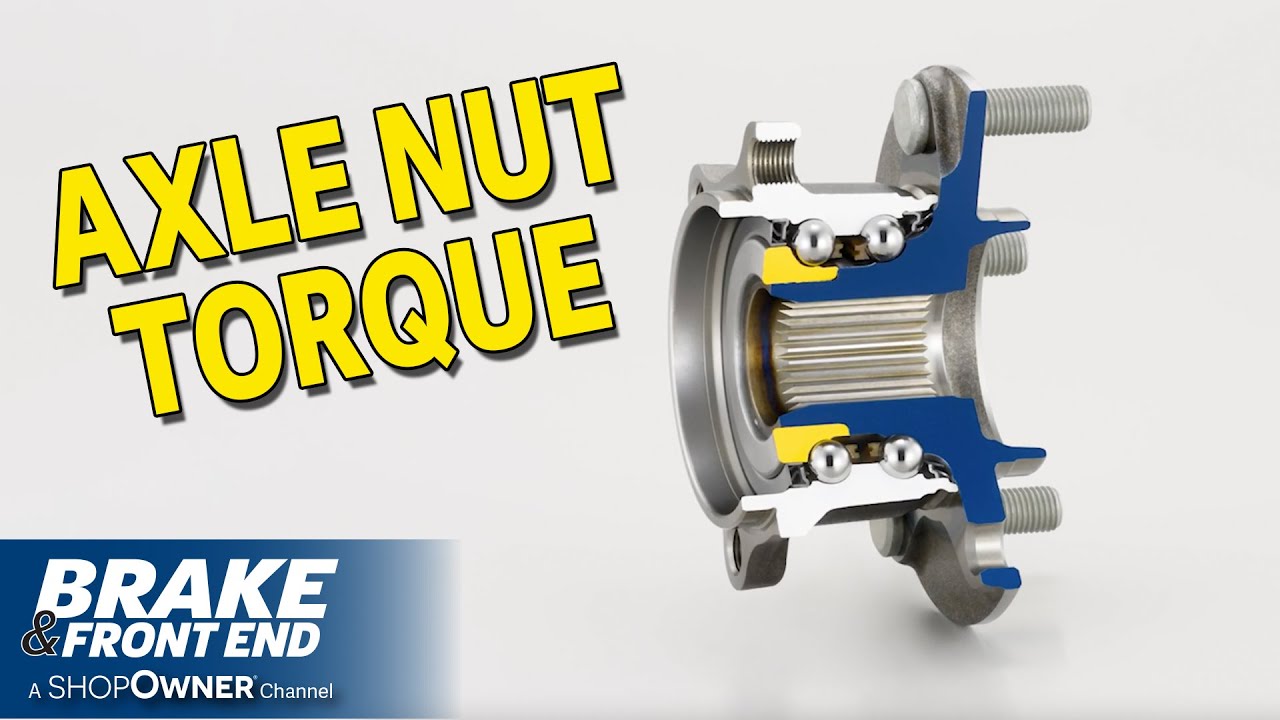

Why is getting the Honda Element's axle nut torque right so vital? The axle nut secures the drive axle to the wheel hub. Incorrect tightening—whether too loose or too tight—can compromise this connection, leading to premature wear, damage, and potential safety hazards. Imagine the consequences of a loose wheel while driving! Proper torque ensures a secure connection, preventing slippage and promoting even wear of crucial components.

The precise Honda Element axle nut torque specification is crucial information for any DIY mechanic or car enthusiast. While a general range exists, referring to your specific Element's year and model in the owner's manual is essential. This manual will provide the manufacturer-recommended torque value, ensuring the best possible outcome for your vehicle. Using the correct torque specification prevents over-tightening, which can damage the wheel studs or hub, and under-tightening, which risks wheel detachment. Using a calibrated torque wrench is paramount for accurate application of the required torque.

Historically, axle nut torque has been a critical factor in automotive safety. As vehicles evolved and speeds increased, the importance of secure wheel attachments became even more pronounced. Standardized torque specifications emerged as a vital part of vehicle maintenance, ensuring consistent and reliable wheel assembly. Today, manufacturers like Honda provide detailed torque specifications for every model, emphasizing the continued importance of this often-overlooked detail.

Understanding the implications of incorrect Honda Element axle nut fastening is crucial for proactive maintenance. Under-torqued axle nuts can lead to vibrations, wheel wobble, and ultimately, wheel separation. Over-torquing, on the other hand, can strip the wheel studs or damage the hub, requiring costly repairs. Regularly checking the axle nut torque, especially after tire rotations or brake work, is a simple yet effective way to prevent these issues.

One of the main benefits of proper axle nut tightening is enhanced safety. Secure wheels are essential for vehicle stability and control, minimizing the risk of accidents due to wheel detachment. Proper torque also contributes to the longevity of wheel bearings, hubs, and axles by ensuring even load distribution and reducing wear and tear. Lastly, it reduces vibrations and noise, contributing to a smoother and more comfortable ride.

A successful axle nut tightening procedure involves several key steps: first, locate the correct torque specification in your Element's owner's manual. Second, gather the necessary tools, including a calibrated torque wrench and the appropriate size socket. Third, carefully tighten the axle nut in a star pattern to the specified torque. Finally, double-check the torque to ensure accuracy.

Advantages and Disadvantages of DIY Axle Nut Tightening

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for incorrect torque if not careful |

| Convenience | Requires investment in tools (torque wrench) |

| Increased knowledge of your vehicle | Risk of damage if procedure isn't followed correctly |

Frequently Asked Questions:

1. What is the torque spec for my Honda Element's axle nuts? Consult your owner's manual.

2. What tools do I need? A torque wrench and the correct size socket.

3. How often should I check the axle nut torque? After tire rotations or brake work, and periodically as part of regular maintenance.

4. What are the signs of a loose axle nut? Vibrations, wheel wobble, or unusual noises.

5. Can I use a regular wrench instead of a torque wrench? It's strongly recommended to use a torque wrench for accurate tightening.

6. What happens if I overtighten the axle nut? You risk damaging the wheel studs or hub.

7. What happens if I undertighten the axle nut? The wheel could come loose, leading to a dangerous situation.

8. Where can I find a torque wrench? Most auto parts stores carry torque wrenches.

In conclusion, understanding and applying the correct Honda Element axle nut torque is a fundamental aspect of vehicle maintenance. This seemingly small detail plays a significant role in safety, performance, and the longevity of crucial components. By following the correct procedures and using the right tools, you can ensure a secure and reliable connection between your wheels and axles, contributing to a smoother, safer, and more enjoyable driving experience. Don't underestimate the importance of proper torque – take the time to familiarize yourself with your Element's specific requirements and invest in a quality torque wrench. Your safety and the well-being of your vehicle depend on it.

Bmw X3 Rear Axle Nut Torque | Kennecott Land

honda element axle nut torque | Kennecott Land

Honda element axle nut torque | Kennecott Land

Torque spec for honda civic tires | Kennecott Land

2006 Honda Accord Front Suspension Diagram | Kennecott Land

Honda Crv Lug Nut Torque Spec | Kennecott Land

Honda axle nut torque spec | Kennecott Land

Honda Lug Nut Torque Chart | Kennecott Land

Honda Lug Nut Torque Specification | Kennecott Land

Honda element axle nut torque | Kennecott Land

honda element axle nut torque | Kennecott Land

Honda Accord Axle Nut Size | Kennecott Land

2000 Honda Crv Lug Nut Size | Kennecott Land

2014 Jeep Cherokee Lug Nut Torque | Kennecott Land

2000 Honda Accord Axle Nut Size | Kennecott Land