Mastering Industrial Electrical Motor Control

Imagine a world without the hum of machinery, the whirring of automated systems, the seamless operation of production lines. This is a world without the power and precision of industrial electricity and motor controls. These systems are the invisible force driving modern industry, enabling everything from automated assembly lines to complex robotic systems. Understanding these fundamental principles is crucial for anyone involved in industrial processes, from technicians and engineers to managers and operators.

The core of modern industry lies in the effective management and application of electrical power. Industrial electricity encompasses the generation, distribution, and utilization of electrical energy within industrial settings. It involves intricate networks of power systems, transformers, switchgear, and protective devices, all working in concert to ensure a reliable and safe power supply. Motor controls are an integral part of this landscape, enabling the precise and efficient operation of electric motors, the workhorses of countless industrial applications.

Resources such as industrial electricity and motor control PDFs offer a valuable gateway into this complex world. These documents often provide comprehensive information on a range of topics, including fundamental electrical principles, motor control techniques, safety procedures, and troubleshooting guidance. They serve as essential learning tools for students, professionals, and anyone seeking a deeper understanding of these vital systems.

The evolution of industrial electricity and motor control has been a journey of continuous innovation, driven by the ever-increasing demands of modern manufacturing. From early manual control systems to sophisticated programmable logic controllers (PLCs), the technology has advanced dramatically, enabling greater precision, efficiency, and automation. These advancements have revolutionized industrial processes, enabling higher productivity, improved quality control, and enhanced safety.

Delving into the specifics, a well-structured industrial electricity and motor control PDF might cover various motor types, including AC motors, DC motors, servo motors, and stepper motors, explaining their operating principles, characteristics, and suitable applications. It would likely also delve into different motor control methods, such as variable frequency drives (VFDs), soft starters, and motor protection relays, highlighting their functionalities and benefits. Such a resource can provide a comprehensive overview of crucial concepts like power factor correction, grounding and bonding, and electrical safety regulations.

One of the key benefits of studying industrial electricity and motor controls is the enhanced ability to troubleshoot and maintain electrical systems. This knowledge empowers technicians to diagnose problems quickly and efficiently, minimizing downtime and maximizing productivity.

Furthermore, a strong understanding of these principles can lead to optimized energy efficiency within industrial settings. By implementing advanced control techniques and selecting appropriate motor technologies, businesses can significantly reduce energy consumption and operating costs.

Finally, prioritizing safety in industrial electrical systems is paramount. Comprehensive training in this area equips personnel with the knowledge and skills necessary to identify and mitigate potential hazards, creating a safer working environment and minimizing the risk of accidents.

A practical example could be using a VFD to control the speed of a conveyor belt in a manufacturing plant, optimizing its operation based on production demands and conserving energy when possible.

Another example might be using a PLC to automate a complex industrial process, coordinating the operation of multiple motors and other equipment with precise timing and control.

A third example is employing motor protection relays to safeguard motors against overloads, short circuits, and other faults, preventing damage to equipment and ensuring the safety of personnel.

Advantages and Disadvantages of Motor Control Systems

| Advantages | Disadvantages |

|---|---|

| Improved efficiency | Initial cost of implementation |

| Enhanced safety | Complexity requiring specialized skills |

One challenge in implementing motor control systems can be the integration of different technologies and communication protocols. A solution might involve employing a standardized communication platform to ensure seamless data exchange between various components.

FAQs

What is a VFD? A Variable Frequency Drive controls motor speed by adjusting the frequency of the power supplied to the motor.

What is a PLC? A Programmable Logic Controller is an industrial computer used to automate industrial processes.

Why is motor control important? Motor control enhances efficiency, safety, and precision in industrial operations.

What are some common motor control devices? VFDs, soft starters, PLCs, and motor protection relays.

How can I learn more about industrial electricity? Several online resources, textbooks, and training programs are available.

What are some safety considerations for industrial electrical systems? Proper grounding, lockout/tagout procedures, and arc flash protection.

What are the different types of AC motors? Induction motors, synchronous motors, and single-phase motors.

What is the role of a motor protection relay? It protects motors from damage due to overloads, short circuits, and other faults.

In conclusion, the world of industrial electricity and motor controls is a dynamic and essential field that underpins modern industry. From powering complex manufacturing processes to enabling precise automation, these systems play a critical role in driving efficiency, productivity, and safety. Understanding the underlying principles, exploring relevant resources like industrial electricity and motor controls PDFs, and embracing best practices are crucial for anyone seeking to navigate this complex landscape. By continuously learning and adapting to technological advancements, we can harness the full potential of these systems and pave the way for a more efficient and automated future. This understanding allows for optimized processes, reduced energy consumption, and enhanced safety protocols, all leading to improved productivity and profitability within the industrial sector. Invest time in learning more about industrial electricity and motor controls to unlock the potential of modern industrial operations.

Industrial Electricity and Motor Controls by Rex Miller OverDrive | Kennecott Land

Industrial Electricity and Motor Controls Second Edition eBook in | Kennecott Land

Electrical Motor Controls Training System | Kennecott Land

Industrial Electricity and Motor Controls | Kennecott Land

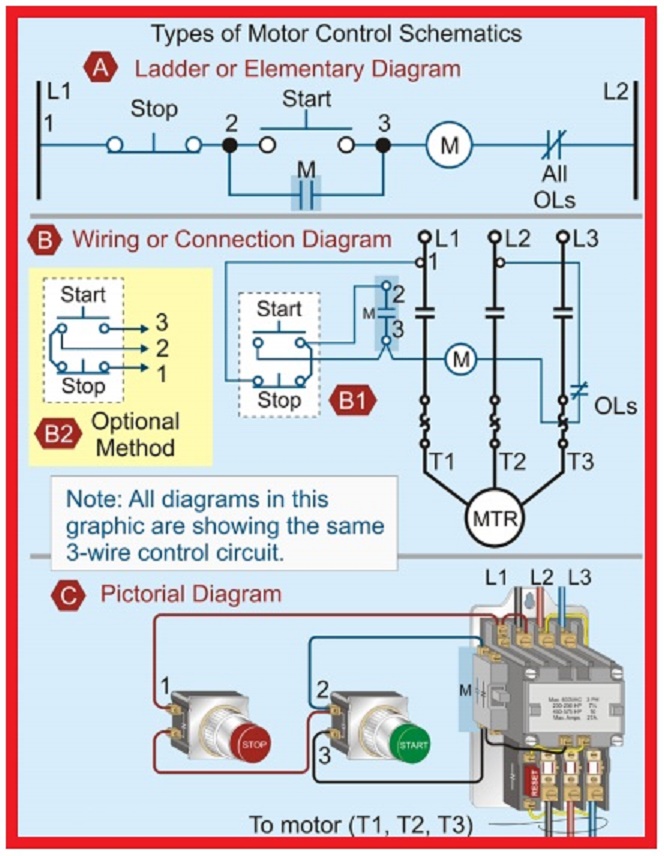

Electrical Motor Control Diagram | Kennecott Land

Electric Motor Control Circuit Diagram Pdf | Kennecott Land

Control Circuit Schematic Diagram | Kennecott Land

Industrial Electricity and Motor Controls Second Edition By Rex Miller | Kennecott Land

Electrical Motor Control Schematics | Kennecott Land