Powering Up 220 Motor Connections

The hum of a powerful motor, the whirring of machinery coming to life – it's a symphony of industrial elegance. But behind this orchestrated power lies the intricate network of wires and connections, the silent conductor of this electromechanical ballet. Understanding the 220 motor wiring diagram is the key to unlocking this power safely and effectively.

Connecting a 220-volt motor isn't just about plugging it in; it's about precision, safety, and ensuring the longevity of your equipment. This guide delves into the nuances of 220V motor wiring schematics, offering a practical understanding of this essential electrical process. From the fundamental principles to the finer details, we'll explore the various aspects of connecting a 220V motor, equipping you with the knowledge to tackle this task with confidence.

The history of electric motor wiring is interwoven with the development of electricity itself. Early motors, often powered by direct current (DC), required complex wiring configurations. The advent of alternating current (AC) and the standardization of voltages like 220V simplified the process, leading to the widespread adoption of electric motors in industry and everyday life. Understanding the historical context of motor wiring allows us to appreciate the advancements that have shaped modern electrical systems.

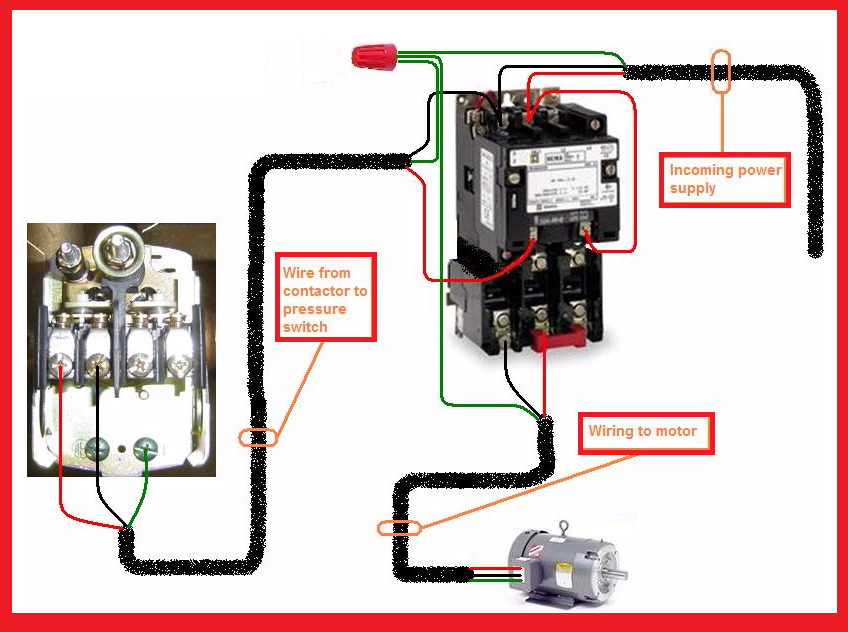

A 220 motor wiring schematic acts as a roadmap, guiding you through the connections necessary to bring your motor to life. It details the power supply connections, the motor terminals, and any additional components like start capacitors or overload relays. Misinterpreting or neglecting this diagram can lead to serious consequences, from motor damage and malfunction to potential electrical hazards. Properly interpreting the schematic is paramount to a successful and safe installation.

The importance of a correctly implemented 220V motor connection setup cannot be overstated. It ensures efficient power delivery, preventing energy waste and optimizing motor performance. A correct wiring scheme also protects the motor from damage caused by voltage fluctuations or incorrect phasing, extending its lifespan and reducing the risk of costly repairs. Moreover, it ensures the safety of the operator and the surrounding environment, mitigating potential electrical hazards.

Several types of 220V motor wiring diagrams exist, catering to different motor configurations and applications. Single-phase motors typically utilize a simpler diagram compared to three-phase motors, which involve more complex connections. Understanding the specific diagram for your motor is crucial. For instance, a single-phase motor might require connections for a start capacitor, while a three-phase motor will necessitate connections for all three phases of the power supply.

Benefits of a correct 220 motor wiring diagram include: 1. Optimized Motor Performance: Correct wiring ensures efficient power delivery, maximizing motor output and minimizing energy loss. 2. Enhanced Safety: Proper wiring reduces the risk of electrical hazards, protecting both the operator and the equipment. 3. Extended Motor Lifespan: Correct connections prevent damage caused by voltage fluctuations or incorrect phasing, prolonging the motor's operational life.

Advantages and Disadvantages of Different 220V Motor Wiring Configurations

| Configuration | Advantages | Disadvantages |

|---|---|---|

| Direct Online Starting (DOL) | Simple, cost-effective | High starting current |

| Star-Delta Starting | Reduced starting current | More complex wiring |

Troubleshooting tips: If your motor isn't running, double-check the wiring diagram, ensure correct voltage supply, and check for any loose connections. Always consult a qualified electrician if you're unsure about any aspect of the wiring process.

FAQ: What's the difference between single-phase and three-phase 220V motors? Single-phase motors use a single AC power supply, while three-phase motors utilize three separate AC supplies, offering greater power and efficiency.

In conclusion, understanding and implementing the correct 220 motor wiring diagram is essential for the safe, efficient, and long-lasting operation of your motor. This meticulous process, akin to the careful stitching of a finely tailored garment, ensures the seamless flow of power, transforming electrical potential into mechanical motion. By taking the time to study the diagram, understand the connections, and follow best practices, you're not just wiring a motor – you're orchestrating the precise dance of electricity, bringing your machinery to life with power and precision. Remember to always consult with a qualified electrician for any complex wiring projects to ensure safety and compliance with electrical codes. The proper wiring of a 220V motor is an investment in the longevity and performance of your equipment, a testament to the power of precision and the elegance of functionality.

Single Phase 220 Volt Wiring Diagram | Kennecott Land

How To Wire A 220 Volt Electric Motor | Kennecott Land

wiring a 220 motor diagram | Kennecott Land

Wiring A 220 Motor Diagram | Kennecott Land

Wiring Diagram For 220 Motor | Kennecott Land

wiring a 220 motor diagram | Kennecott Land

wiring a 220 motor diagram | Kennecott Land

How To Wire A 220 Motor For Air Compressor | Kennecott Land

wiring a 220 motor diagram | Kennecott Land

Single Phase 220v Wiring Diagram | Kennecott Land

How Is 220 Volt Wiring at Elinor Henson blog | Kennecott Land

Electric Motor Wiring Diagrams Explained | Kennecott Land

Single Phase Motor Wiring Diagrams 120 Volt | Kennecott Land