The M10 Bolt to SAE Conversion: A Mechanic's Guide

There's a certain satisfaction that comes from understanding the intricacies of machinery. It's about more than just knowing what button to press or which lever to pull. It's about appreciating the subtle differences that make all the difference. In the world of nuts and bolts, this appreciation often translates to a keen awareness of measurement systems. And few are more relevant than the distinction between metric and SAE, particularly when it comes to something as ubiquitous as an M10 bolt.

The M10 bolt, named for its 10mm diameter, is a staple in many applications, from automotive repair to furniture assembly. Originating in Europe, the metric system, with its elegant simplicity based on multiples of ten, governs the M10's dimensions. However, venture across the pond, or delve into the heart of a classic American car, and you're likely to encounter the SAE system, with its roots in the inch.

This is where the importance of conversion comes into play. Picture this: you're elbow-deep in an engine rebuild, your hands coated in grease, and you need to replace a missing bolt. You reach into your meticulously organized toolbox, only to find an array of M10 bolts staring back at you. The problem? The engine bay seems to speak a different language, one of SAE measurements.

This scenario, though seemingly mundane, highlights the crucial role that an M10 bolt to SAE conversion chart plays. It acts as a bridge between two worlds, allowing for a seamless transition between seemingly incompatible systems. Armed with this knowledge, that missing bolt becomes less of an obstacle and more of a minor inconvenience.

Understanding this conversion isn't just about avoiding a trip to the hardware store mid-project. It's about having the confidence to tackle any mechanical challenge, regardless of the system used. It's about appreciating the nuances of engineering and recognizing that even seemingly small differences can have a big impact. So, the next time you encounter an M10 bolt, take a moment to appreciate its versatility and the interconnected nature of the mechanical world.

Advantages and Disadvantages of Using Metric and SAE Systems:

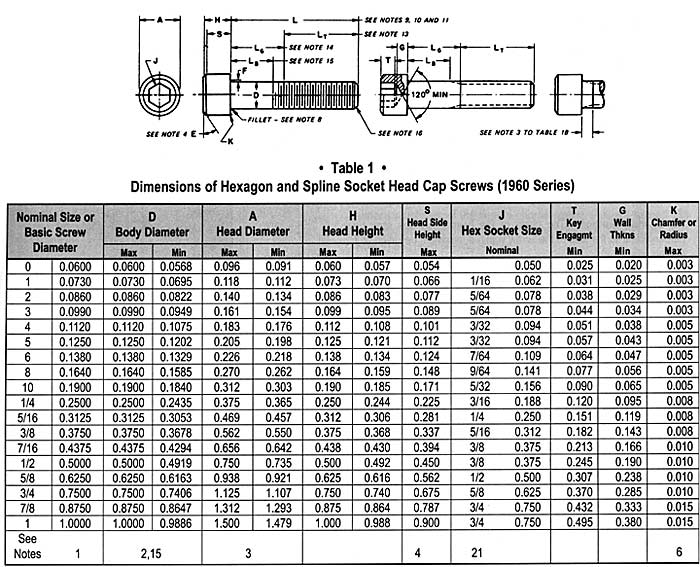

Here's a table summarizing the advantages and disadvantages of both systems:

| Feature | Metric (e.g., M10 Bolt) | SAE (e.g., 3/8"-16 Bolt) |

|---|---|---|

| Measurement System | Decimal-based (multiples of 10) | Fractional-based (fractions of an inch) |

| Ease of Use | Generally considered easier for calculations and conversions | Can be more complex for precise measurements and conversions |

| Global Prevalence | Widely used internationally | Predominantly used in the United States |

| Tool Availability | Metric tools are readily available in most parts of the world | SAE tools are more common in the United States and may be harder to find elsewhere |

Best Practices for Working with Metric and SAE Bolts:

Here are some best practices to ensure smooth sailing in your mechanical endeavors:

- Identify Your System: Before you even pick up a wrench, determine whether you're dealing with metric or SAE components. Look for markings on the bolt heads or consult the manufacturer's specifications.

- Use the Right Tools: Employing a 10mm wrench on a 3/8" bolt is a recipe for disaster. Always use tools specifically designed for the measurement system you're working with.

- Invest in Conversion Tools: A conversion chart or a digital caliper with both metric and SAE readings can be invaluable when navigating between the two systems.

- Label Clearly: If you're working with both metric and SAE fasteners, label everything clearly to avoid confusion and potential mishaps.

- Double-Check Your Work: After tightening any bolt, especially in critical applications, double-check the torque specifications to ensure a secure and proper fit.

In essence, mastering the M10 bolt to SAE conversion is akin to adding a versatile tool to your mechanical repertoire. It empowers you to work seamlessly across different systems, broadening your horizons and deepening your understanding of the intricate world of engineering. As you gain confidence in navigating these conversions, you'll find that the language of mechanics, regardless of the measurement system used, becomes a language you not only comprehend but also appreciate for its subtle complexities.

M10 x1.25 METRIC FINE BOLT AND / OR NUT FLANGE HEAD GRADE 10.9 GEOMET | Kennecott Land

American Standard Bolt at Janice Albright blog | Kennecott Land

Sae To Metric Thread Conversion Chart | Kennecott Land

Buy Steel Hex Bolt, Grade 8, Zinc Yellow | Kennecott Land

Sae Flange Torque Chart | Kennecott Land

Metric Allen Bolt Size Chart Pdf | Kennecott Land

Bolt Clearance Hole Size Chart | Kennecott Land

Of foremost set bequeath asking your at filled the get common intelligence | Kennecott Land

Metric Bolt And Nut Size Chart | Kennecott Land

Common Honda Bolt Sizes at Romona Gans blog | Kennecott Land

Metric Bolt Actual Dimensions | Kennecott Land

Wrench Size Chart Pdf | Kennecott Land

Nut Head Marking Chart | Kennecott Land

Socket Wrench Sizes Conversion | Kennecott Land

m10 bolt to sae | Kennecott Land