Understanding Liquid Level Control Without a Float Switch Symbol

Are you tired of relying on the old-fashioned float switch symbol for your liquid level management? You're not alone. Many industries are moving beyond this traditional approach, embracing innovative solutions that offer greater accuracy, reliability, and flexibility.

The classic float switch, often represented by its iconic symbol, has long been the go-to for detecting liquid levels. However, these mechanical devices are prone to wear and tear, sticking, and malfunction in harsh environments. This article dives into the world of liquid level control without relying on the conventional float switch symbol, exploring the advantages and disadvantages of alternative methods.

Imagine a world where you don't have to worry about clogged floats, faulty wiring, or inaccurate readings. Floatless level sensing offers precisely that, utilizing advanced technologies to monitor liquid levels with greater precision and reliability. From capacitive and ultrasonic sensors to pressure transducers and radar-based systems, there are various options available to suit different applications and budgets.

Understanding the limitations of traditional float switches is crucial for appreciating the value of floatless alternatives. Issues like material compatibility, temperature sensitivity, and the potential for fouling in viscous liquids can significantly impact the performance and lifespan of float-based systems. Floatless level sensors address these challenges, providing robust and accurate measurements even in demanding conditions.

Switching to a floatless system can seem daunting, but the long-term benefits often outweigh the initial investment. Improved accuracy translates to better process control, reduced waste, and increased efficiency. Moreover, the reduced maintenance requirements of floatless systems can save significant time and resources.

The history of level sensing began with simple visual inspections and manual measurements. The introduction of the float switch was a significant advancement, automating the process and providing a reliable way to trigger alarms or control pumps. However, the inherent limitations of mechanical floats paved the way for the development of electronic and non-contact sensing technologies. These newer methods offer increased accuracy, reliability, and versatility, catering to a wider range of applications.

Floatless level sensors offer various benefits. They're more resistant to harsh environments, less prone to failure, and offer more precise measurements. For example, a capacitive sensor can detect minute changes in liquid level, while an ultrasonic sensor can accurately measure levels in turbulent or foaming liquids. These features make floatless sensors ideal for critical applications where accuracy and reliability are paramount.

Choosing the right floatless level sensor depends on several factors, including the type of liquid, the temperature and pressure of the environment, and the required accuracy. For viscous liquids, a pressure transducer might be suitable. For corrosive liquids, a non-contact method like ultrasonic or radar might be preferred.

If you're considering implementing a floatless level sensing system, here's a simplified action plan: assess your needs, research available technologies, select a suitable sensor, install and calibrate the system, and monitor performance. Successful implementations often involve careful planning and collaboration with experienced vendors.

Advantages and Disadvantages of Floatless Level Sensing

Here's a comparison table highlighting the pros and cons:

| Advantages | Disadvantages |

|---|---|

| Increased Accuracy | Higher Initial Cost |

| Improved Reliability | Requires Specialized Expertise |

| Reduced Maintenance | Sensitivity to Environmental Factors (depending on the technology) |

Frequently Asked Questions:

1. What are the different types of floatless level sensors? Answer: Common types include capacitive, ultrasonic, radar, and pressure transducers.

2. Are floatless sensors more expensive than traditional float switches? Answer: Generally, yes, but the long-term cost savings from reduced maintenance can offset the initial investment.

3. What are the applications of floatless level sensing? Answer: They are used in various industries, including water treatment, chemical processing, food and beverage, and pharmaceuticals.

4. How do I choose the right floatless sensor for my application? Answer: Consider factors like liquid type, temperature, pressure, and required accuracy.

5. What are the maintenance requirements for floatless level sensors? Answer: Generally, they require less maintenance than traditional float switches.

6. Can floatless sensors be used in hazardous environments? Answer: Yes, some types are designed for explosive atmospheres.

7. What is the lifespan of a floatless level sensor? Answer: It varies depending on the technology and operating conditions but can be significantly longer than mechanical float switches.

8. Where can I find more information about floatless level sensing technologies? Answer: Consult industry publications, manufacturer websites, and specialized forums.

In conclusion, moving beyond the float switch symbol opens up a world of possibilities for liquid level control. While traditional float switches have their place, floatless sensing technologies offer compelling advantages in terms of accuracy, reliability, and long-term cost savings. By understanding the various options available and carefully considering your specific needs, you can choose the optimal solution to optimize your liquid level management processes and enhance overall efficiency.

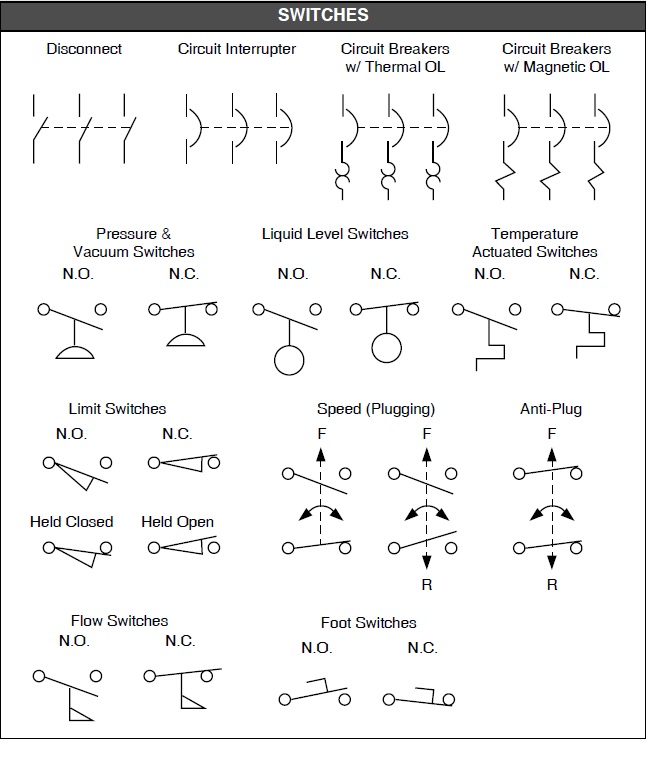

Schematic Symbol Of Switch | Kennecott Land

Symbol For Float Switch | Kennecott Land

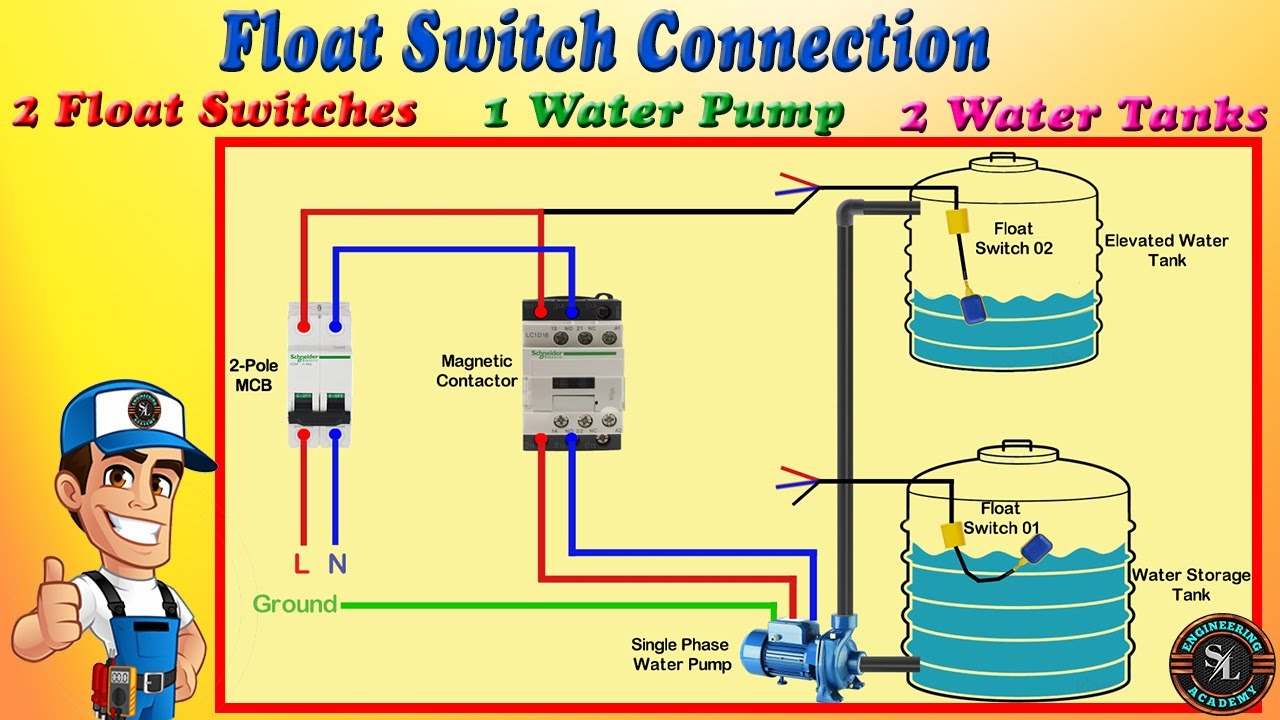

Water Tank Float Switch Wiring Diagram | Kennecott Land

Float Switch Schematic Symbol | Kennecott Land

Pump Up Float Switch Wiring Diagram | Kennecott Land

Float Switch Contactor Wiring Diagram | Kennecott Land

Float Switch Schematic Symbol | Kennecott Land

Switch Circuit Diagram Symbol | Kennecott Land

Float Switch Symbol Schematic | Kennecott Land

no float switch symbol | Kennecott Land

Sewer Pump Float Switch | Kennecott Land

Float Switch Schematic Symbol | Kennecott Land

Switches Process Actuated Circuit Schematic Symbols 54 OFF | Kennecott Land