Unleash the Power: Rubber Band Car Design for Speed & STEM

Ever wondered how to transform simple household items into a mini speed demon? Rubber band powered cars offer a fascinating glimpse into the world of physics and engineering, providing a hands-on learning experience for all ages. These ingenious contraptions, powered by the potential energy stored in a wound-up rubber band, are more than just toys; they’re a gateway to understanding fundamental scientific principles.

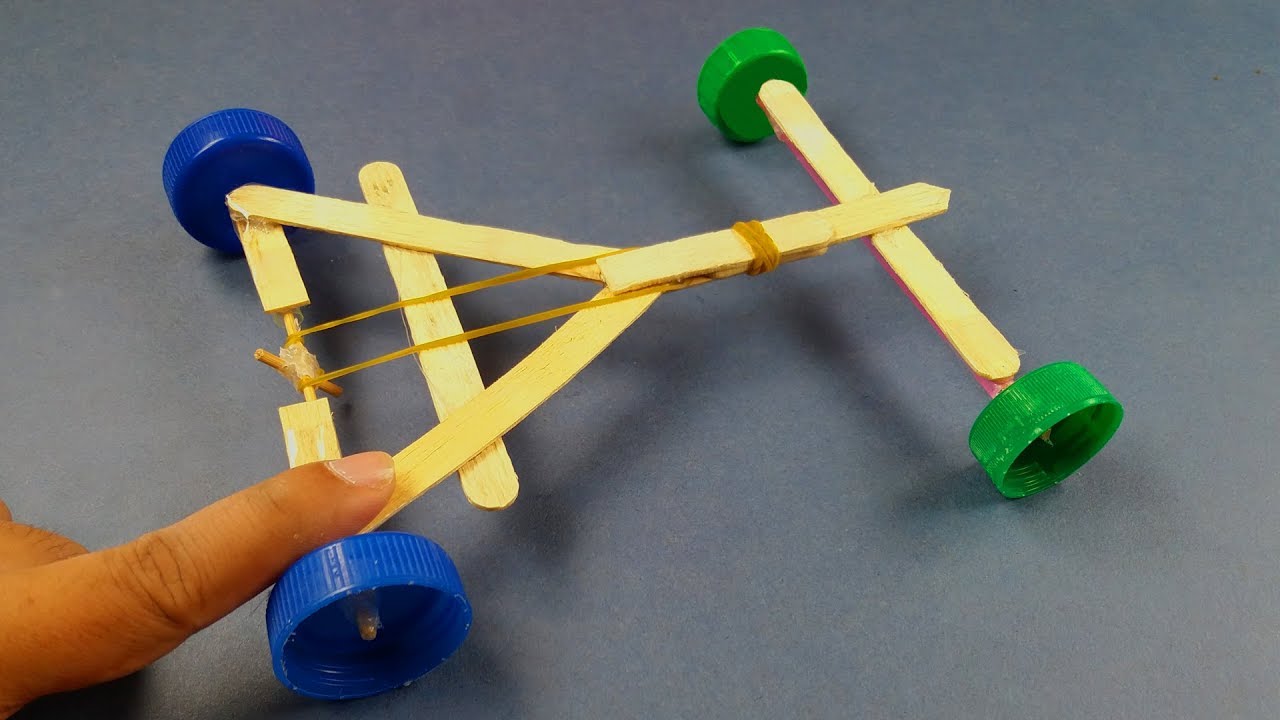

Rubber band powered car construction isn't just about slapping together some cardboard and wheels. A well-designed vehicle involves careful consideration of factors like aerodynamics, weight distribution, and friction. The goal is to maximize the transfer of energy from the rubber band to the wheels, propelling the car forward with maximum efficiency. This involves exploring different chassis designs, wheel configurations, and even experimenting with different types of rubber bands.

The history of rubber band powered cars is intertwined with the development of rubber itself. While pinpointing the exact origin is difficult, these DIY vehicles have been a popular educational toy and science project for generations. Their enduring appeal stems from their simplicity and the tangible demonstration of energy conversion. They offer a low-cost, accessible way to explore physics concepts like potential and kinetic energy, friction, and Newton's laws of motion.

A core challenge in rubber band car design lies in optimizing energy transfer. Friction is the enemy, robbing the system of precious kinetic energy. This makes material selection and axle design crucial. Smooth, low-friction axles and lightweight materials can significantly improve performance. Another challenge involves winding the rubber band effectively without overstressing it, which could lead to breakage or inconsistent power delivery.

Building a rubber band powered car involves understanding a few key definitions. The "chassis" is the main body of the car, providing structural support. The "axles" are rods that connect the wheels, allowing them to rotate. "Friction" is the force that resists motion between two surfaces in contact. A simple example of reducing friction in a rubber band car is using straws or small tubes as bearings around the axles, allowing them to spin more freely.

One major benefit of rubber band powered car projects is their educational value. They provide a practical application of scientific concepts, making learning engaging and memorable. For example, experimenting with different wheel sizes demonstrates the relationship between wheel circumference and distance traveled. Another benefit is the development of problem-solving skills. Building and refining a design requires critical thinking and experimentation to overcome challenges and improve performance.

To build your own rubber band car, start with a sturdy chassis material like cardboard or balsa wood. Attach axles, made from dowels or skewers, securely to the chassis. Next, mount wheels onto the axles, ensuring they rotate freely. Create a system for attaching and winding the rubber band, connecting it to the rear axle to propel the car forward. Test and refine your design by adjusting factors like wheelbase, weight distribution, and rubber band tension.

Advantages and Disadvantages of Rubber Band Powered Cars

| Advantages | Disadvantages |

|---|---|

| Educational and engaging | Limited power and range |

| Low-cost and accessible | Can be fragile |

| Promotes problem-solving skills | Performance is sensitive to environmental factors |

FAQs:

1. What type of rubber band works best? - Thicker rubber bands generally provide more power.

2. How can I make my car go faster? - Reduce friction, optimize weight, and use a powerful rubber band.

3. What materials can I use for the chassis? - Cardboard, balsa wood, or even recycled plastic bottles.

In conclusion, rubber band powered car design offers a captivating blend of science, engineering, and creativity. From understanding basic physics principles to developing problem-solving skills, building these miniature vehicles is a rewarding experience. The ability to design, build, and test your own creation provides a tangible sense of accomplishment and fosters a deeper appreciation for the power of simple mechanics. So, gather your materials, unleash your inner engineer, and experience the thrill of building your own rubber band powered speed machine! Explore the endless possibilities of this engaging activity and discover the fun and learning that awaits. This simple project can spark a lifelong interest in STEM fields and empower the next generation of innovators.

How to Make a Rubber Band Powered Car Project and Designs | Kennecott Land

Rubber Band Powered Car Design | Kennecott Land

Rubber Band Powered Car Project | Kennecott Land

Fast Food Chain Components Rubber Band Powered Car | Kennecott Land

Wheels Toy Car Project at Gregory Reed blog | Kennecott Land

Science Behind Rubber Band Car | Kennecott Land

Rubber Band Powered Car Science Project | Kennecott Land

StoneOak Media STEM Inventor | Kennecott Land

How To Make A Rubber Band Powered Race Car | Kennecott Land

9 best images about Rubber Band Powered Car Ideas on Pinterest | Kennecott Land

Building A Rubber Band Powered Car | Kennecott Land

rubber band powered car | Kennecott Land

Designing a Simple 3D Printed Rubber Band Car Using Autodesk Fusion 360 | Kennecott Land

StoneOak Media STEM Inventor | Kennecott Land

Science Behind Rubber Band Car | Kennecott Land